The Supply Chain Game is an online simulator where you can expand and manage a network of factories and warehouses to supply new markets in new regions on the fictional continent of Pangea. Please navigate through all the buttons above to learn more about the assignment, including instructions for managing your network.

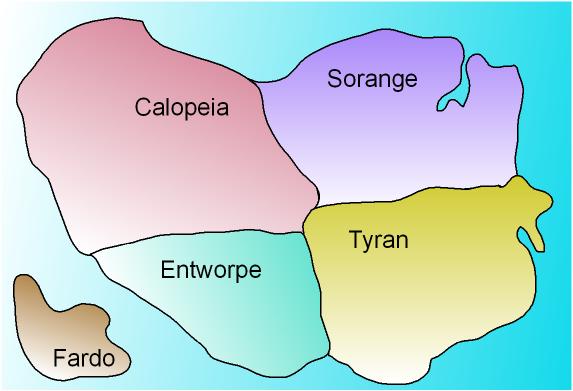

PANGEA

Jacobs Industries’ only product is an industrial chemical that can be mixed with air to form a foam that is:

Jacobs sells to manufacturers of products that will pay a premium for foam insulators with these properties. All of Jacobs’ customers purchase the foam chemical as a substitute for competitors’ products. If Jacobs cannot meet the order when it is received, the customer makes its purchase from a competitor without any loss of future demand.

Jacobs began marketing to manufacturers of air conditioner retrofit kits on day 1 and on day 640 began tracking demand in four new markets. Click the Marketing button above, or Next > below for those regional details.

Jacobs will eventually migrate to a new technology using a different supply chain network. This new foam technology will render the current technology obsolete. Factories producing the new foam will come online on day 1460. All customers are aware of the pending new technology and, as a result, demand will decrease linearly beginning at day 1430, reaching 0 on day 1460.

The original application of the foam was for kits to retrofit or repair old industrial air conditioners. The properties of the foam made it possible to improve the efficiency of existing air conditioners within the constraints imposed by existing facilities. The industry that builds and sells these kits is concentrated entirely in Calopeia. The market is highly seasonal but otherwise very stable. There are no long-run market trends, either upward or downward. The size of orders is very random with an average size of 7 or 8. Orders also arrive randomly.

Hardwood floors are coming back into fashion. A common product addressing this market is a laminated wood panel that is made to snap together to easily cover a floor. However, poor acoustic properties of the laminates have been a problem in apartment buildings and condominiums where sound is easily transmitted to downstairs neighbors. Manufacturing of the laminates is concentrated in Sorange and two large manufacturers of laminates have recently added premium product lines with better acoustic insulation. Those laminates are a market for Jacobs’ foam chemical.

Although order size and arrivals are random, the long run average demand will grow linearly from day 640 until day 1430. The average order size is about 8 drums and demand is not seasonal.

Customers of premium home appliances, especially driers and dishwashers, are willing to pay a premium for sound insulation. An appliance manufacturer with factories in Tyran and Fardo is offering a premium acoustic insulation option on several of its high-end appliances. Those appliances are a market for Jacobs’ foam chemical.

Orders arrive to Jacobs directly from the appliance factories. Both order size and order arrivals are random. Demand began on day 640 and grew to its final long-run average a month later. Long-run average demand is not seasonal and is not trending either upward or downward. The average order size is about 8 drums.

A single manufacturer supplies insulating quilts for insertion into walls in new construction projects where both wall thinness and thermal insulation are important. These projects include laboratories inside office buildings and saunas inside commercial gyms. The quilts are a market for Jacobs’ foam chemical.

The quilt manufacturer uses a reorder point policy where 250 units are purchased whenever its inventory drops to a predetermined level. So although orders are always for 250 units, orders arrive randomly. Demand started on day 640 and was stable by day 670. Long-run average demand is not seasonal and is not trending either upward or downward.

A make-to-order assembler of single-engine airplanes uses the foam as an insulator. The order size and order timing are random, although the average order quantity is about the same as that of the appliance factories in Fardo and Tyran described earlier. Demand began on day 640 and stabilized by day 670. Long-run average demand is not seasonal and is not trending either upward or downward.

Jacobs’ distribution network consists of a single factory and a single warehouse, both in Calopeia. The warehouse only supplies air conditioner retrofit kit manufacturers, who are all in Calopeia.

Jacobs produces its chemical in batches, loads the chemical into small plastic drums, and then transports the drums to the warehouse by truck. The warehouse sends drums to customers as orders are received.

About a year and a half into operations, Jacobs began looking for new markets and discovered a handful of industries where Jacobs foam would be a superior substitute for the insulating foam currently used in those industries. Marketing campaigns for these target customers began on day 640. Regular communication with its target customers allows Jacobs to monitor the demand for its product in each of the new markets. However, Jacobs had not begun actually selling to any of the new markets yet. Jacobs is only selling to the original market in Calopeia.

Jacobs management would like to serve the new markets it has identified if serving those markets is profitable. However, serving those markets could be logistically complex. Some decisions to be made include

You have been hired to make these decisions. Your goal is to maximize cash position generated by the foam technology over its lifetime. On day 1460, the technology will be obsoleted by another technology currently in development.

A factory can only produce one batch a time. The more capacity a factory has, the faster it produces a batch of a given size. The cost of a factory building is $500,000 regardless of the factory capacity. The cost of factory equipment and fixtures is proportional to capacity: Capacity of one drum per day costs $50,000. For example, the cost to build a new factory with a capacity of 5 drums per day is $500,000 + (5)$50,000 = $750,000. Adding an additional capacity of 2 drums per day later would cost (2)50,000 = $100,000.

It takes 90 days to either construct a new factory or to add capacity to an existing factory. The cost of the factory is incurred as soon as construction begins. Capacity cannot be retired.

Production in factories is carried out in batches, where each batch is an integer number of drums set by you. The cost to produce one batch equals $1500 plus the number of drums in the batch times $1000. For example, the cost to produce a batch of 10 drums is $1500 + (10)$1000 = $11,500.

A new warehouse costs $100,000. There is no practical limit to the number of drums a warehouse can hold. It takes 60 days to build a warehouse and the cost of the warehouse is incurred as soon as construction begins.

Jacobs pays insurance and other out-of-pocket holding costs on chemicals once production is complete. These holding costs for one drum for one year is $100, whether the drum is en route to a warehouse or the drum is physically in a warehouse. There are no such holding costs for work-in-process inventory in the factory.

Finished drums are shipped from the factory to the warehouse as soon as production is completed. The drums can be shipped by either truck or mail. One truck can carry 200 drums. If the batch is less than 200 drums, then less than a truckload will be used. The cost of full or less-than-full truckload is the same. If drums are shipped by mail, the shipping cost is proportional to the number of drums being mailed.

Transportation costs are as follows:

| Origin and Destination | Cost per Truckload | Cost to Mail One Drum |

|---|---|---|

| Same region | $15,000 | $150 |

| Different regions on continent | $20,000 | $200 |

| Between continent and Fardo | $45,000 | $400 |

Transportation times are as follows:

| Origin and Destination | Truck | |

|---|---|---|

| Same region | 7 days | 1 day |

| Different regions on continent | 7 days | 1 day |

| Between continent and Fardo | 14 days | 2 days |

All customers will pay $1450 per drum. The drum must be shipped within 24 hours of receiving the order or the order is lost. Warehouses may partially fill orders and one order may be filled from multiple warehouses.

All order fulfillment is by mail, so the cost to fulfill an order is:

Interest accrues on cash at 10% per year, compounded daily.

Your team has been hired to manage the supply chain for the Jacobs Industries. You can make the following changes to the supply chain:

Your objective is to maximize the cash generated by the foam technology over the remaining two years of its lifetime. On day 1460 the game will end and all inventory and capacity will be obsolete.

The simulation will run continually at the rate of 104 simulated days per real day, or 1 simulated day about every 14 minutes. You will have control of the game from day 730 to day 1460, or 730 days total. The game will conclude 7 days and about half an hour after it started. During that time you can access your supply chain any time of the day or night.

The winning team is the one with the highest cash position on day 1460.

After the game is over, your team should turn in a 4-page memo describing the actions you took and in retrospect, whether there were other choices that would have allowed your team to do even better. You will graded on the use of conceptual tools from class that you use to justify your conclusions.

You will play with the same team as in the first game. To make any changes to your team name, team password, or the students’ names on the team, you can go back to the registration page, enter the code again, then enter your team name and password you created earlier, and make your changes.

Once the game has started, you may not modify your team.

Once the game has begun you can access your firm by logging in using your team name and password.

If you have popup blocker, you will need to allow popups from the web site. Also, if you have modified your security settings, make sure you have not disabled cookies. There are some less common problems that students sometimes have:

Click here to open a new window and log in.

After you log in, you will see three icons in the Calopeia region: headquarters, a factory, and a warehouse, You are allowed a maximum of one factory and one warehouse in each of the other four regions. A black factory or warehouse icon signifies the factory or warehouse is currently operational. A gray icon signifies the factory or warehouse is under construction. To begin construction of a new factory or a new warehouse, click on the region where you would like to begin construction and fill in the resulting form.

Clicking on each icon will open a window presenting buttons to view historic data and make changes:

|

Plot past demand, past lost demand, and your firm’s past cash position. |

|

Plot past WIP inventory, add production capacity, and change order point, order quantity, and shipping method. |

|

Plot past finished goods inventory and shipments, and change order point, order quantity, and shipping method. |

The terms in the forms are hyperlinked to more detailed definitions.

The menu bar below the map of Pangea provides additional functions: